Process Mining: evidence at the service of improvement

We already know that digital transformation is much more than implementing technology. At Izertis we use the formula of digital metamorphosis which, although etymologically identical, has a more revolutionary character at an internal and external level in companies.

So far, digitalisation processes have involved the implementation of technology, and in particular of large management systems: the best ERPs, the best CRMs, warehouse management systems, the best logistics applications, etc.

How can process mining help companies?

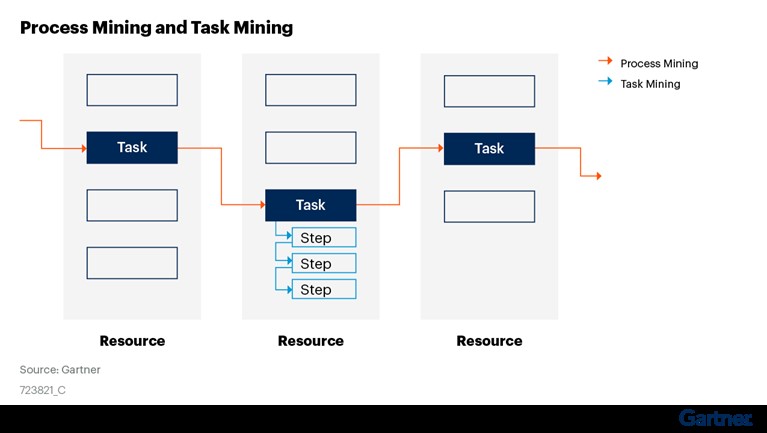

Thanks to process mining, companies can go a step further in the efficient use of these technologies, as it makes it possible to extract all the information that these systems contain in their infinite logs, so that companies can get to know themselves a little better. Thanks to process mining, it is possible to know which tasks are carried out in a given process, managed through any of the large systems on the market. It is therefore a technology that will accelerate the metamorphosis processes in many companies.

The great advantage of process mining is that it is based on evidence, on real data obtained from the systems already in place, and is more objective than other tools such as process mapping workshops used for analysis or re-engineering.

Process mining tools build a trace that allows us to draw the processes for which we use these tools, showing their degree of variation, deviations and errors with respect to the most travelled path, or the ideal that the company has established.

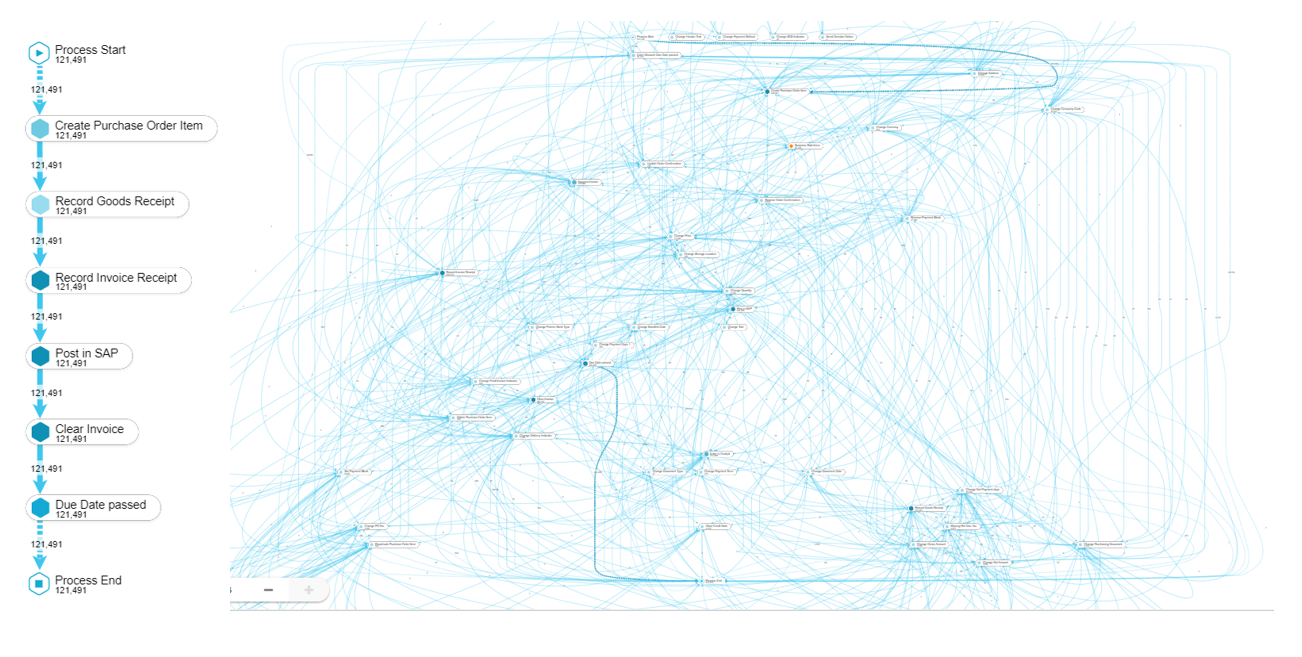

This is how the so-called spaghetti graphs are formed where, around this ideal or most common case of the process, hundreds of variants of the process begin to orbit. This is a visual example of the Lean concept of "mura", that kind of waste linked to irregularity. Process mining systems not only allow us to know how many process variants there are, but also the number of total processes executed in each of these variants.

Imagine, for example, a purchasing department. By applying process mining in purchase-to-order, we could find out how many paid invoices have taken advantage of or wasted early payment discounts, how many of them would have been worth delaying payment in order to obtain a better financial condition, or which ones have been paid twice. Large companies are saving significant amounts of money simply by avoiding duplicate invoice payments. In addition, these systems allow the information to be disaggregated to find out which groups of suppliers have the highest number of conflicting purchases, in order to try to start resolving the most pressing cases.

Process mining provides evidence of what is really going on in a company's processes, its AS-IS

EMS, an effective tool for process management

In general, due to the importance of the volume of information generated in the systems, process mining has so far been developed in large companies, whose immensity of extracted logs allows them to have better information of the processes to elaborate their flowcharts. However, its implementation in small and medium-sized growing companies will give them the opportunity to eliminate inefficiencies before they become larger.

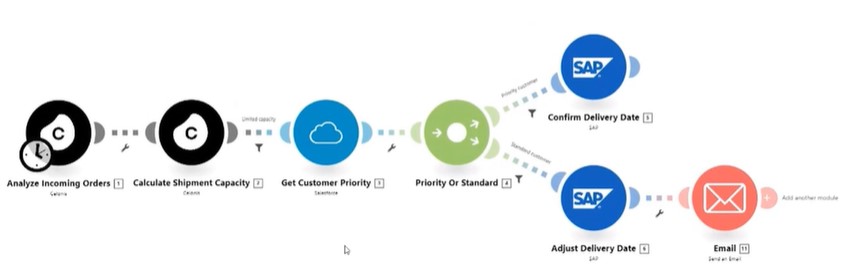

An important improvement has been the arrival on the market of the so-called EMS, or Execution Management Systems, which not only include process mining, but are also capable of easily orchestrating flow re-engineering, without the need to leave the tool itself and in real time. To do so, they use simple, highly visual connectors that involve the most common ERPs or CRMs on the market.

This simplicity in the reconstruction of flows means that these tools go from being used by specialists or developers to being used by analysts in the first instance and, gradually, by all employees of the organisation who incorporate analytical skills into their functions that allow conclusions to be drawn and improvements to be proposed.

From this we can infer the crucial role, once again, of the change management required by companies engaged in process mining and re-engineering at these levels. Implementation experiences show that, while it is not difficult to convince, it is difficult to involve staff in the day-to-day work. It is therefore recommended not only to train and communicate, but also to propose small changes and make them work. Once again, senior management sponsorship will be key to success.

Process mining provides evidence of what is really going on in a company's processes, its AS-IS. Understanding the current process makes it possible to know its variations, lack of performance and where to invest in improvements to establish the TO-BE. It also does so in an integrated way with the business management systems themselves in a direct, accurate and graphic diagnosis, which allows management to make decisions. Its implementation in combination with orchestrators and hyper-automation technologies represents a scientific revolution in process improvement.